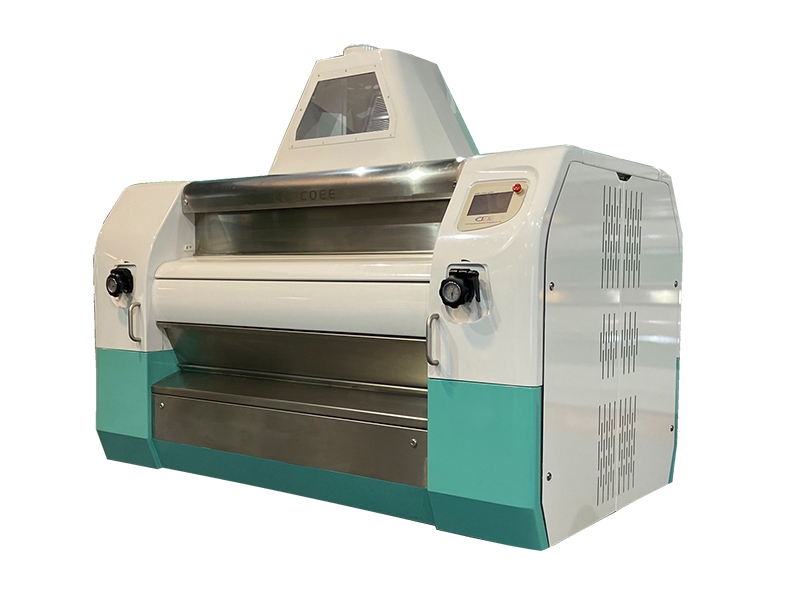

MMR Roller mill

MMR mill is a high – end product, leading the future market. The contact part of material uses food – grade 304 stainless steel, no dead angle, no residue;

Convenient to flip the feed unit, easy to clean the feeding area;

The grinding roller unit, a spin off from the grinding body assembly, convenient operation, reducing paring time;

Variable speed feeding, the feeding will increase to the limit, changing the feeding environment, improving the grinding quality, saving energy;

Permanent magnet synchronous motor speed control, and more efficient than ordinary motor, cleaner;

Tooth elastic wedge band tensioning device, can self – compensate the micro – change and improve the service life of the band;

The whole case iron base, higher stability of equipment.

Major Parameters

| Model | MMR25/80 | MMR25/100 | MMR25/125 |

| Roller (mm) | Φ250×800 | Φ250×1000 | Φ250×1250 |

| Range of Applicable Roller (mm) | Φ230-250 | ||

| Fast Roll Rotating Speed (m/s) | 450-460 | ||

| Fast-slow Roller Dating Speed Ratio | 1.25:1 1.5:1 2:1 2.5:1 | ||

| Feeding Roll Speed Ratio | 1:1 1.4:1 1.5:1 1.67:1 2:1 | ||

| Motor Power(kW) | 37、30、22、18.5、15、11、7.5、5.5 | ||

| Main Drive Wheel Diameter | Φ360 | ||

| Working Air Pressure(Mpa) | 0.6 | ||

| Weight(kg) | 2700 | 3200 | 3800 |

| Dimension (mm) | 1610x1458x1880 | 1810x1458x1880 | 2060x1458x1880 |

We’re Here to Help.

Why Choose Us

Reliable On-Time Delivery

Backed by strong production capacity and efficient logistics systems, we guarantee on-schedule delivery for both domestic and international projects, helping you stay on track and on budget.

Rigorous Quality Assurance

As an ISO-certified manufacturer with national engineering laboratories, we adhere to strict quality control standards and apply advanced testing systems to ensure the reliability, safety, and durability of every piece of equipment.

Comprehensive One-Stop Service

From project consultation and layout design to technical training and after-sales support, we provide full-cycle services tailored to your needs—making us your trusted partner in the grain and oil processing industry.

Global Experience & Trusted Brand

As a key subsidiary of COFCO Group (a Fortune Global 500 enterprise), our equipment is trusted in over 30 countries, with a proven track record in helping clients succeed in both emerging and developed markets.