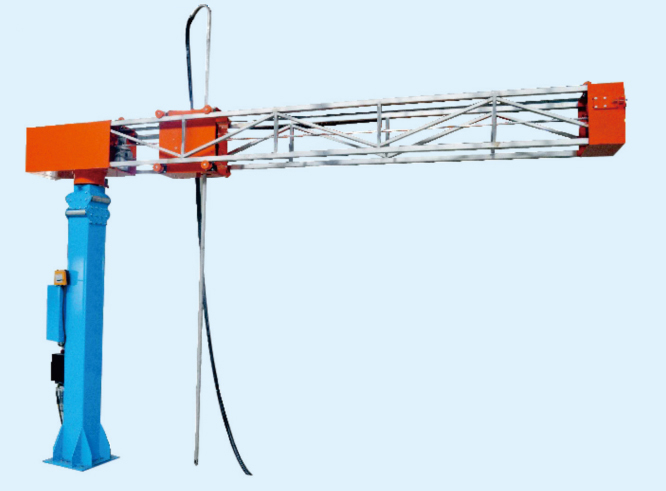

JQY Automatic Grain Sampler

The JQY Automatic Grain Sampler is an advanced device designed to facilitate efficient and representative sampling of grains in various settings, including grain depots, collection centers, and processing facilities. Its high level of automation and adaptability ensures precise sampling, enhancing quality control measures in grain handling operations.

Key Features:

Efficient Sampling Capability: Utilizes a single-tube side-hole sampling device, which reduces resistance and allows deep sampling, even in grains with small sizes.

High-Level Automation: The Z-axis can automatically ascend and descend before warehousing, streamlining the sampling process.

Flexible Movement and Control: The X-axis is linked to the sampler, allowing a 270-degree free rotation, enabling comprehensive coverage during sampling.

Automatic Adaptation: Capable of sampling both bulk and packed grains, accommodating various vehicle sizes and grain types.

Enhanced Safety: Equipped with anti-collision features and an emergency stop button to ensure operator and equipment safety.

Major Parameters

| name | Power(KW) | Voltage(V) | Rotation angle | Distance(mm) | Remark |

| X axismove distance | – | – | – | 3500 | Customization of user requirements |

| Z axis move distance | – | – | – | 2000 | Customization of user requirements |

| Sampling device move distance | – | – | – | 4000 | Customization of user requirements |

| Sampling device rotation angle | – | – | 0~270° | – | |

| Electric power board | – | 380 | – | – | |

| Controlled rotary machine | 0.55 | 380 | – | – | |

| Horizontal motor | 0.55 | 380 | – | – | |

| Sampling device lifting motor | 0.55 | 380 | – | – | |

| Hydraulic control motor | 3 | 380 | – | – | |

| Fan motor | 3 | 380 | – | – |

We’re Here to Help.

Why Choose Us

Reliable On-Time Delivery

Backed by strong production capacity and efficient logistics systems, we guarantee on-schedule delivery for both domestic and international projects, helping you stay on track and on budget.

Rigorous Quality Assurance

As an ISO-certified manufacturer with national engineering laboratories, we adhere to strict quality control standards and apply advanced testing systems to ensure the reliability, safety, and durability of every piece of equipment.

Comprehensive One-Stop Service

From project consultation and layout design to technical training and after-sales support, we provide full-cycle services tailored to your needs—making us your trusted partner in the grain and oil processing industry.

Global Experience & Trusted Brand

As a key subsidiary of COFCO Group (a Fortune Global 500 enterprise), our equipment is trusted in over 30 countries, with a proven track record in helping clients succeed in both emerging and developed markets.